Introduction

Pressure is a critical parameter in industries ranging from water management to oil & gas pipelines and HVAC systems. Traditional pressure monitoring often requires wired infrastructure or costly GSM modules, limiting scalability and flexibility.

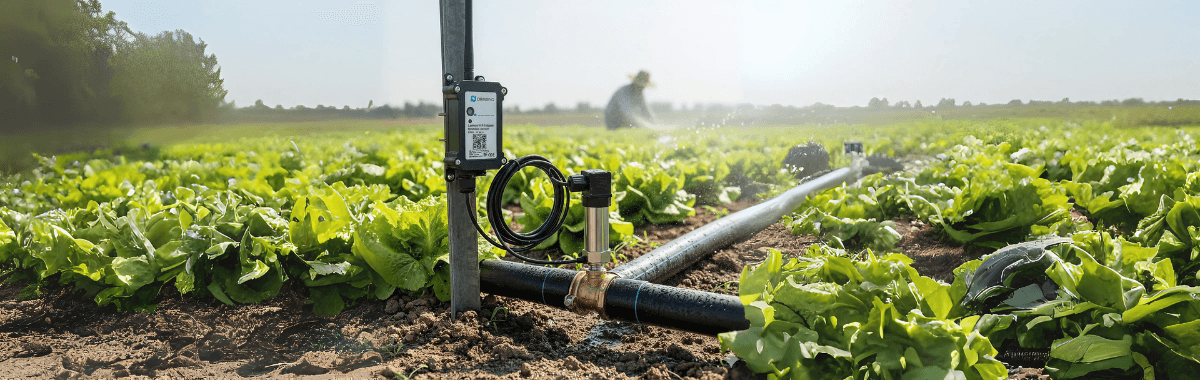

The Dragino PS-LB LoRaWAN® Pressure Sensor provides a wireless, low-power, long-range solution for continuous pressure monitoring. With LoRaWAN® connectivity, it can transmit data over several kilometers while consuming minimal power, making it ideal for smart industry, agriculture, and infrastructure projects.

In this blog, we’ll explore how to install, handle, and maintain the PS-LB effectively for accurate and reliable pressure monitoring.

Why Pressure Monitoring Matters

- Water Management: Detect pipeline leaks, monitor irrigation pumps, and ensure water distribution efficiency.

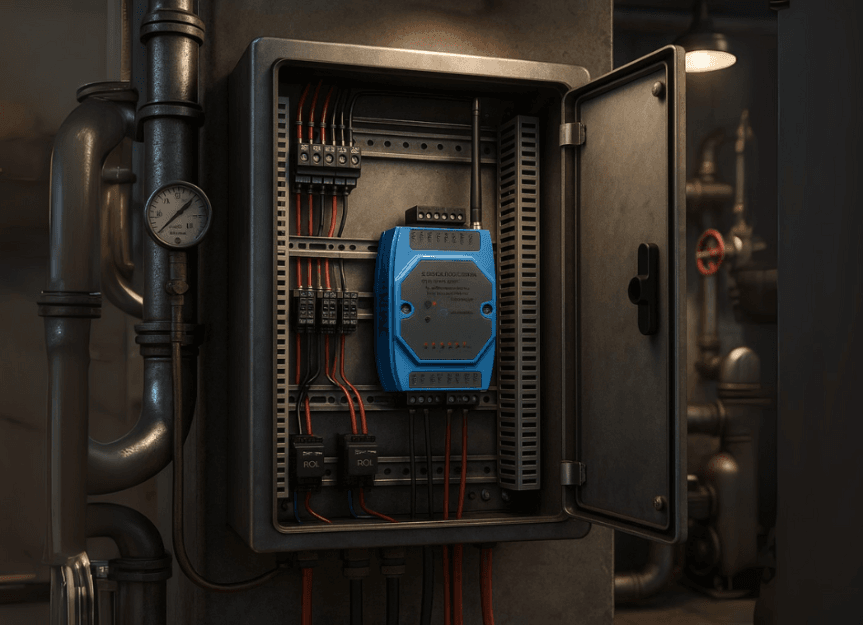

- Industrial Safety: Maintain safe operating pressures in boilers, tanks, and pipelines to prevent accidents.

- Predictive Maintenance: Monitor real-time pressure changes to prevent costly equipment failures and downtime.

- Energy Efficiency: Optimize pump and compressor operations to reduce electricity consumption and operational costs.

Device Overview: Dragino PS-LB

- Function: Monitors pressure in liquid or gas pipelines.

- Connectivity: LoRaWAN® Class A, ultra-low power, long-range communication.

- Measurement Range: Depends on sensor variant (commonly 0–1 MPa, 0–10 MPa, etc.).

- Design: Stainless steel probe with rugged housing, weatherproof for outdoor installations.

- Power: Battery powered with long life (multi-year operation).

- Integration: Compatible with LoRaWAN® servers (TTN, ChirpStack) and cloud dashboards.

How to Install the PS-LB Effectively

- Identify the Monitoring Point: Install at critical points such as pipeline inlets, pump stations, tanks, or compressors. Ensure accessibility for maintenance and calibration.

- Mounting the Pressure Probe: Use the correct thread fitting (typically G1/4 or NPT) to securely connect the probe to the pipe or tank port. Apply thread sealant or PTFE tape to prevent leaks. Avoid overtightening, which could damage the sensor.

- Device Body Placement: Mount the LoRaWAN® sensor body above ground level, ideally on a wall or pole. Keep the antenna upright for maximum signal strength. Ensure the device housing is protected from direct water splashes, even though it is weatherproof.

- Power & Activation: Insert the battery according to the user manual. Register the device on your LoRaWAN® server using its DevEUI, AppEUI, and AppKey. Confirm uplinks before leaving the site.

Handling & Maintenance

- Calibration: Sensors are factory-calibrated but may require recalibration in critical applications.

- Cleaning: Wipe the probe with a soft cloth; avoid corrosive cleaning agents.

- Leak Check: Regularly inspect connections for leaks or corrosion at the threaded port.

- Battery Management: Monitor voltage via uplink messages and replace batteries before they drop below the recommended threshold.

Real-World Applications

The Dragino PS-LB LoRaWAN® Pressure Sensor has versatile applications across multiple industries. In smart agriculture, it monitors irrigation pipelines to detect leaks and optimize pump usage, helping farmers save water and reduce labor. Water utilities benefit by installing the sensor on underground mains, enabling early leak detection and minimizing water loss. In the oil and gas sector, the PS-LB tracks pressures in pipelines and storage tanks, enhancing operational safety and allowing early anomaly detection. Industrial plants can monitor HVAC and compressed air systems, reducing energy consumption and enabling predictive maintenance for equipment.

The Results

- Improved Reliability: Continuous pressure monitoring ensures consistent operation, reduces unplanned downtime, and provides confidence in system integrity.

- Faster Leak Detection: Early identification of pressure anomalies allows utilities and industries to address issues before they escalate, minimizing losses and preventing damage.

- Cost Savings: Optimized operation of pumps, compressors, and pipelines lowers energy consumption and maintenance costs, improving overall operational efficiency.

Key Lessons

- Correct Installation is Vital: Properly securing the probe and ensuring correct thread connections are essential for accurate and reliable measurements.

- LoRaWAN® Reduces Complexity: Wireless communication eliminates the need for extensive wiring or costly GSM solutions, simplifying deployment across large facilities.

- Regular Maintenance Extends Sensor Life: Periodic leak inspections, cleaning, and battery management are crucial to maintaining sensor accuracy and long-term performance.

Conclusion

The Dragino PS-LB LoRaWAN® Pressure Sensor delivers accurate, wireless, and energy-efficient pressure monitoring for industrial and agricultural systems. Its long-range connectivity, rugged design, and low-power operation make it an ideal solution for smart infrastructure monitoring. By following proper installation, handling, and maintenance practices, organizations can achieve reliable performance, enhanced safety, operational efficiency, and reduced operational costs over the long term.

Keep Exploring Our Blog Collection

LoRaWAN® Antenna Gain and Coverage

When organizations deploy LoRaWAN® networks at scale, one of the most over...

Learn More

Getting Started with Dragino LT-22222-L

In IoT and automation projects, monitoring sensors is only half the story ...

Learn More

Pro Tips for Dragino SPH01-LB LoRaWAN® Soil pH Sensor

Soil health is at the heart of sustainable agriculture. Among the critical ...

Learn More

LoRaWAN® vs Cellular: The Scalable IoT Choice

LoRaWAN® and Cellular technologies both serve as powerful communication options ...

Learn More