Introduction

In IoT and automation projects, monitoring sensors is only half the story—the ability to control equipment remotely is equally important. From switching irrigation pumps to controlling lights or factory equipment, remote actuation saves time, energy, and manpower.

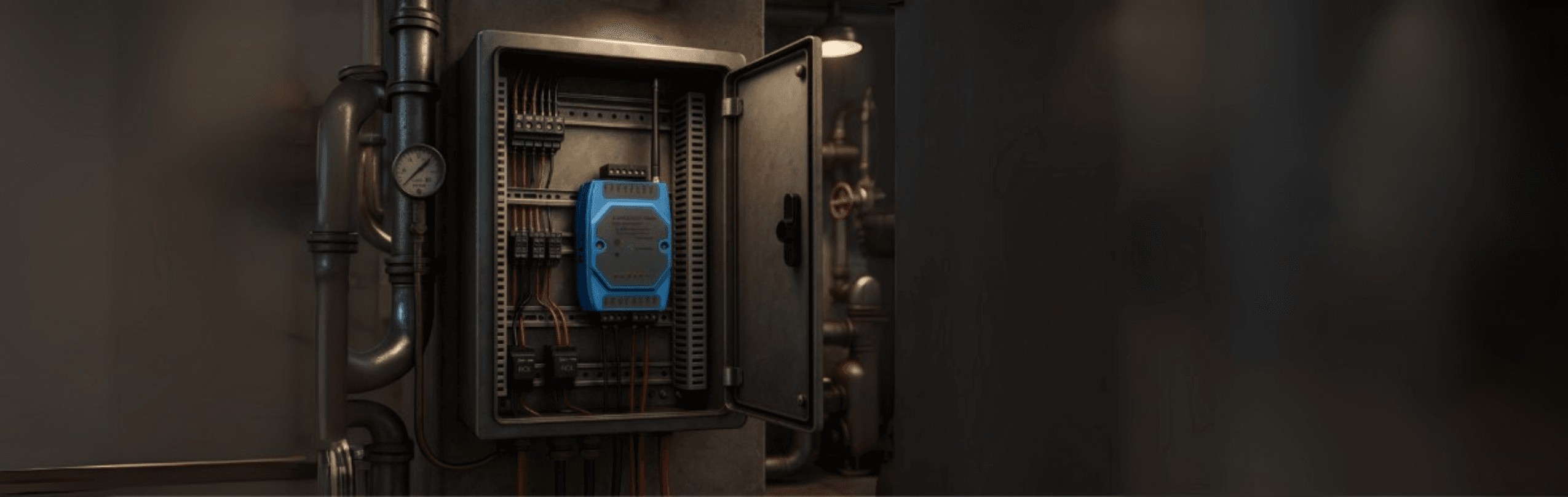

The Dragino LT-22222-L LoRaWAN® I/O Controller enables long-range, low-power wireless control of external devices via LoRaWAN® networks. It combines multiple digital inputs, relay outputs, and analog inputs to serve as a versatile edge controller in agriculture, industrial automation, and smart city deployments.

This blog explores how to install, handle, and maintain the LT-22222-L effectively for reliable remote operations.

Why Remote Control Matters in IoT

Operational Efficiency: Switch equipment on/off without manual intervention.

Energy Savings: Automate pumps, lights, and motors based on schedules or sensor inputs.

Safety: Shut down systems remotely during emergencies.

Scalability: Control multiple devices across large areas with a single LoRaWAN® gateway.

Device Overview: Dragino LT-22222-L

Inputs/Outputs: 2 × Analog Inputs (0–20 mA, 0–30 VDC), 2 × Digital Inputs, 2 × Relay Outputs

LoRaWAN® Connectivity: Long-range, low-power Class A device.

Control Modes: Supports uplink reports and downlink commands for real-time actuation.

Power: Wide power supply range (5–36 VDC).

Rugged Housing: Suitable for industrial and outdoor cabinet installations.

Integration: Works with TTN, ChirpStack, and other LoRaWAN® network servers.

How to Install the LT-22222-L Effectively

Mounting the Device: Install inside an industrial control cabinet or weatherproof outdoor box. Keep away from high-voltage interference sources.

Wiring the Inputs/Outputs: Connect analog sensors (e.g., pressure, temperature, and current sensors) to analog inputs. Wire switches or alarms to digital inputs. Connect pumps, motors, or relays to output terminals. Ensure load current does not exceed rated relay capacity.

Powering the Device: Supply 5–36 VDC from a regulated source. Check polarity before connecting to avoid damage.

Network Setup: Register device credentials (DevEUI, AppEUI, AppKey) on your LoRaWAN® server. Verify uplink reports from inputs and test downlink commands for outputs.

Handling & Maintenance

Relay Protection: Use external protection for inductive loads (motors, pumps) to prevent relay damage.

Firmware Updates: Keep the controller firmware updated for new features and security patches.

Regular Testing: Perform periodic functional tests of inputs and outputs.

Cable Management: Label and secure wiring for easier maintenance.

Real-World Applications

The Dragino LT-22222-L LoRaWAN® I/O Controller has versatile applications across different sectors. In smart agriculture, it enables remote irrigation pump control based on soil moisture data, helping farmers reduce both water usage and labor costs. Smart cities benefit by using the device to control streetlights through LoRaWAN® downlink commands, resulting in lower energy bills and automated lighting schedules. In industrial automation, the LT-22222-L enhances operational efficiency and worker safety by allowing factory equipment to be controlled remotely. For utilities, it provides reliable monitoring of tank levels and the ability to control pumps, ensuring continuous and automated water distribution.

The Results

Labor Savings: Reduced manual switching tasks by up to 40%, allowing personnel to focus on higher-value operations.

Energy Efficiency: Optimized control of pumps, lights, and other equipment reduces energy consumption and lowers operational costs.

Faster Response: Instant remote activation or shutdown of devices via LoRaWAN® downlinks ensures timely intervention during critical situations.

Key Lessons

Proper Wiring Is Crucial: Correct and secure connections are essential to prevent operational failures and ensure system reliability.

Downlink Reliability Matters: Strong LoRaWAN® gateway coverage is necessary for timely and consistent device actuation.

Respect Relay Ratings: Always consider relay specifications and protect outputs, especially when controlling inductive loads such as motors or pumps.

Conclusion

The Dragino LT-22222-L LoRaWAN® I/O Controller effectively bridges the gap between monitoring and control in IoT systems. Its combination of analog inputs, digital inputs, and relay outputs offers a versatile, reliable, and scalable solution for remote control applications across agriculture, industrial automation, smart cities, and other infrastructure environments. By implementing proper installation, wiring, and maintenance practices, organizations can achieve enhanced efficiency, safety, and operational flexibility.

Keep Exploring Our Blog Collection

Installation Guide for Dragino PS-LB

Pressure is a critical parameter in industries ranging from water management to ...

Learn More

LoRaWAN® Antenna Gain and Coverage

When organizations deploy LoRaWAN® networks at scale, one of the most over...

Learn More

Pro Tips for Dragino SPH01-LB LoRaWAN® Soil pH Sensor

Soil health is at the heart of sustainable agriculture. Among the critical ...

Learn More

LoRaWAN® vs Cellular: The Scalable IoT Choice

LoRaWAN® and Cellular technologies both serve as powerful communication options ...

Learn More