Dragino PS-LB for Remote Pressure Monitoring: Data Insights on Pipelines & Storage Tanks Pressure

Automobile Industry

Chennai

Pain Points

Industries & municipalities struggle with real-time pressure monitoring in pipelines, tanks, and fluid systems.

Lack of Continuous Pressure Monitoring

Operators rely on manual gauges or intermittent SCADA sampling, often missing critical pressure fluctuations.

Safety and Compliance Risks

Unmonitored pressure changes in water, gas, or chemical systems risk equipment failure, safety issues, and non-compliance.

Remote Site Connectivity Limitations

Pressure points in remote sites lack wired networks, making timely data collection and monitoring difficult.

Our Offerings

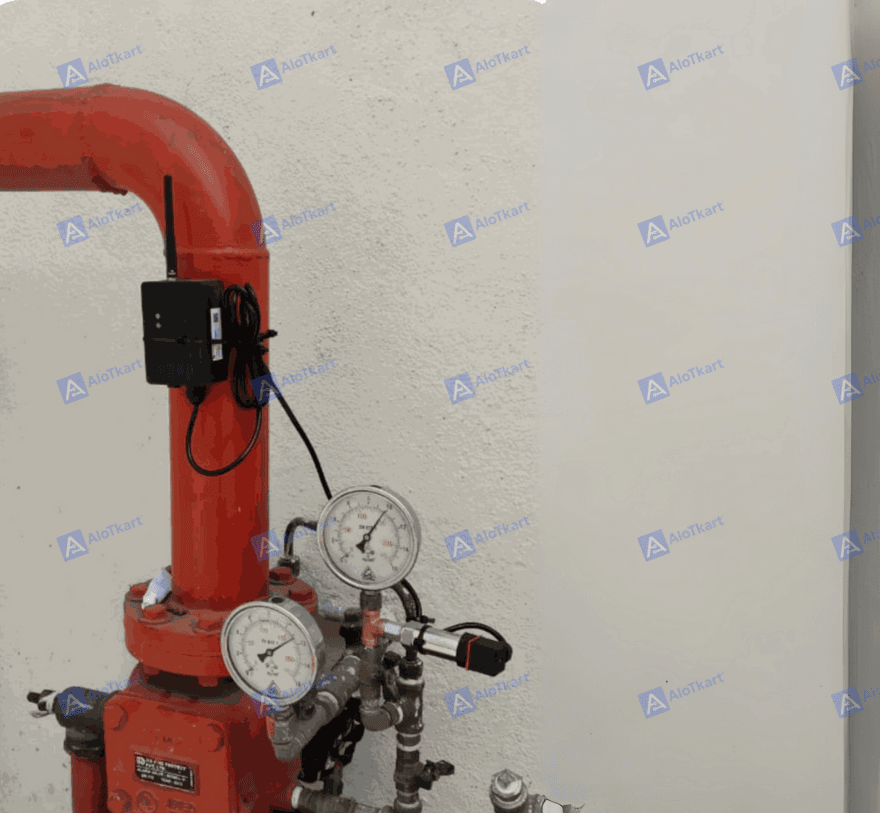

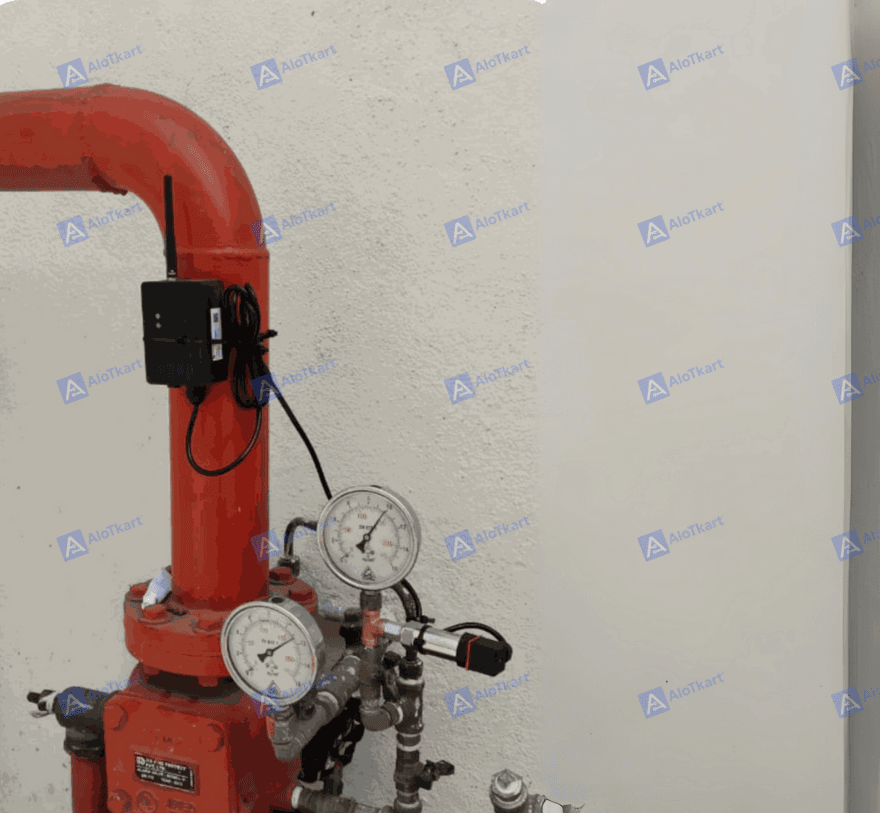

Deployed smart pressure sensors for accurate pressure measurement and automated real-time monitoring.

Remote Pressure Measurement

PS-LB sensors measure liquid & gas pressure and send data via LoRaWAN®, reducing the need for manual inspections.

Flexible Deployment

Compact & rugged, PS-LB installs in pipelines, tanks, wells, or outdoors, delivering reliable performance in all conditions.

Long-Range LoRaWAN® Transmission

LoRaWAN® sends sensor data kilometers to gateways, avoiding costly cellular or wired infrastructure.

Centralized Cloud Monitoring & Alerts

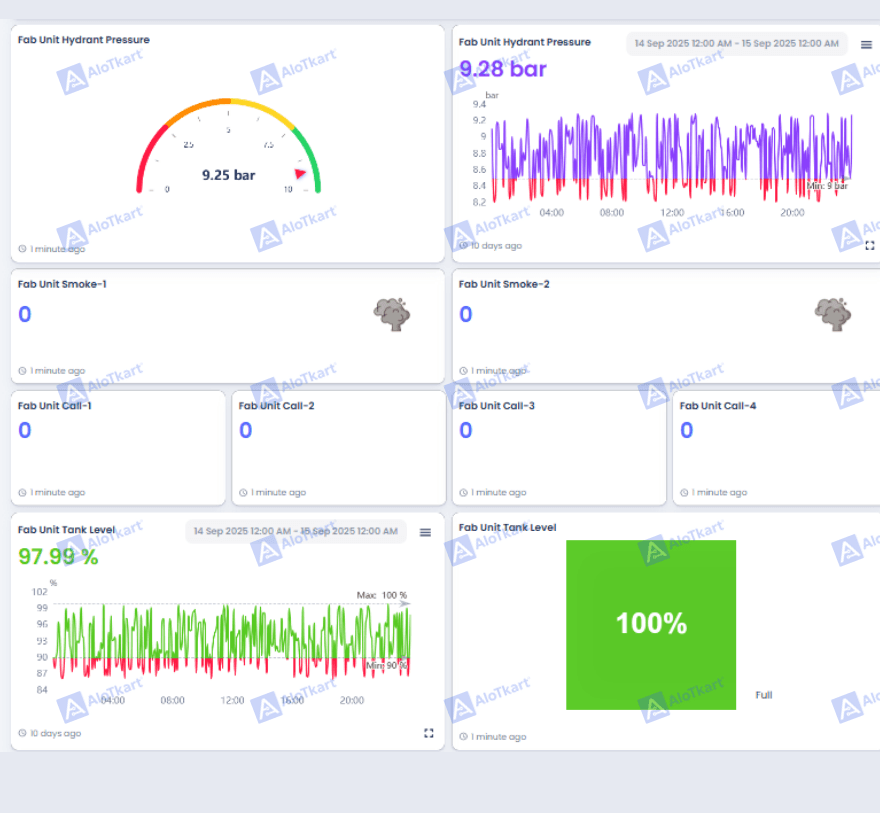

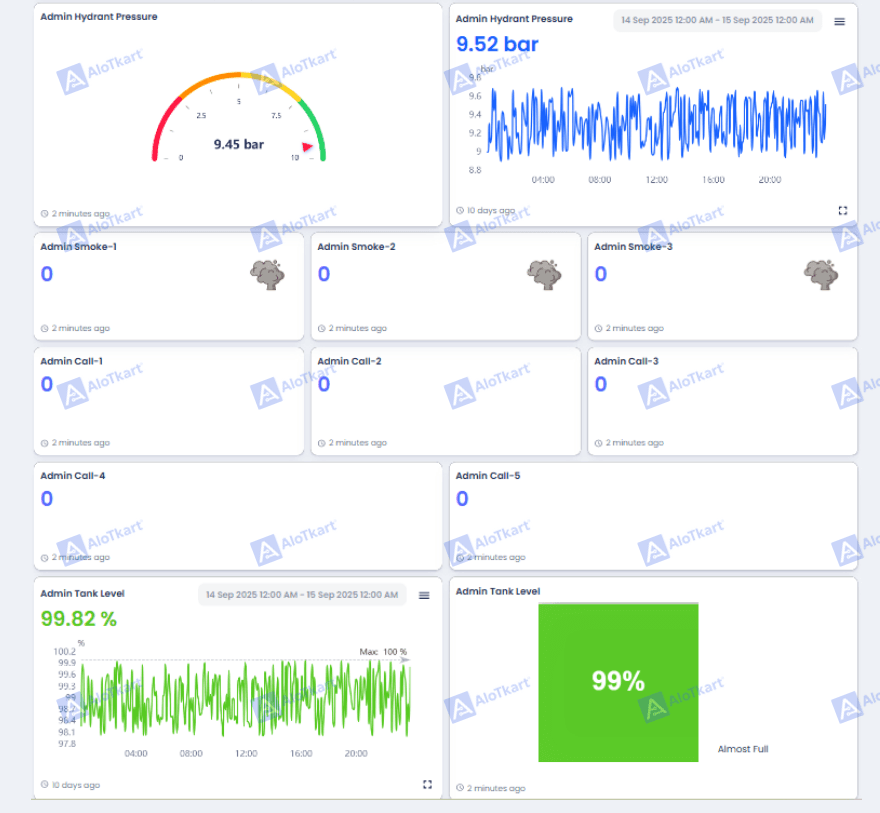

Data flows to LoRaWAN® servers & dashboards for real-time views, automated alerts, and historical analysis.

Outcomes

Continuous System Visibility

Operators receive real-time pressure data for proactive maintenance and operational decision-making.

Enhanced Safety & Compliance

Early detection of abnormal pressure events reduces the risk of system failures or safety incidents.

Cost Reduction

Remote wireless monitoring cuts labor and avoids costs of installing large wired monitoring infrastructure.

Scalable Monitoring Networks

Multiple PS-LB sensors across sites feed into one LoRaWAN® network, enabling centralized monitoring and oversight.